McCormick Industries, a precision CNC machining leader in advanced technologies, has strengthened its operational efficiency, knowledge retention, and quality control by implementing ProShop’s digital manufacturing ecosystem. As a company dedicated to continuous improvement, McCormick Industries has leveraged ProShop’s advanced features to streamline processes, enhance documentation, and ensure superior precision in its manufacturing operations.

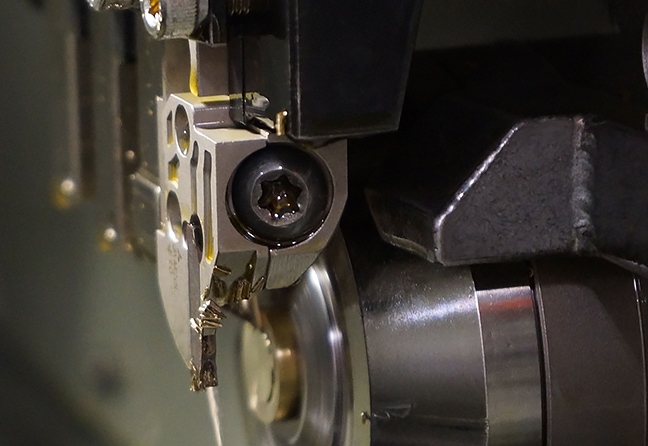

With a reputation for producing small, complex parts for industries such as aerospace, defense, medical, and industrial applications, McCormick Industries has always prioritized efficiency and accuracy. The adoption of ProShop’s paperless digital operating platform (DOP) has allowed the company to consolidate multiple software programs into a single, fully integrated system. From estimating and scheduling to quality control and shipping, real-time access to critical data has optimized workflow efficiency while minimizing redundancies.

One of the most significant advantages McCormick Industries has experienced with ProShop is the improvement in its Quality Management System (QMS). ProShop’s QMS functionality seamlessly integrates with ERP and MES modules, allowing McCormick Industries to track, analyze, and report quality metrics with precision. This has been especially beneficial during audits, as all required documentation is instantly accessible.

“The ability to retrieve detailed records with just a few clicks has been a game-changer for us,” said Gary Hermsen, CEO of McCormick Industries. “During a recent ISO audit, ProShop enabled us to present all necessary documentation in an instant, reinforcing our commitment to quality and compliance. It has streamlined our processes and given us greater confidence in our reporting capabilities.”

McCormick Industries has also benefited from ProShop’s ability to capture and retain earned knowledge from experienced employees. Prior to implementing ProShop, critical shopfloor expertise often resided with specific individuals, creating challenges when those employees were unavailable or left the company. By documenting processes within ProShop, McCormick Industries has ensured that knowledge is preserved and accessible to all employees.

One notable example occurred in the company’s packaging operations. For years, a single employee managed all packaging, possessing an intricate understanding of how to protect parts during shipment. When that employee unexpectedly departed, much of this valuable knowledge was lost. By integrating detailed instructions and photos into ProShop, McCormick Industries has eliminated this risk, ensuring that any trained team member can now handle packaging with the same level of precision.

A similar challenge arose in the company’s mechanical assembly department, where a long-time employee had maintained exclusive knowledge of assembly procedures. Without documented processes, inefficiencies and delays became apparent. Recognizing the need for standardized procedures, McCormick Industries used ProShop to document workflows, complete with step-by-step instructions and fixture locations. As a result, multiple employees are now trained and capable of performing assembly work as needed, ensuring flexibility and continuity.

“We’re not using everything ProShop has to offer just yet,” Hermsen added. “But like with our packaging and assembly processes, we’re making great progress in capturing and centralizing shopfloor knowledge. More importantly, we’re empowering our employees to contribute to this knowledge base, which ultimately strengthens our entire operation.”

Beyond documentation and workflow optimization, ProShop has enhanced communication and accessibility on the shop floor. At McCormick Industries, ProShop is available on computers stationed at every machine tool and across various departments, giving employees instant access to job information, material availability, and scheduling details. This eliminates unnecessary back-and-forth between employees and managers, reducing downtime and increasing overall efficiency.

As a company that prides itself on delivering high-quality parts at competitive pricing, McCormick Industries continues to explore new ways to optimize its operations. ProShop’s comprehensive digital manufacturing ecosystem aligns with the company’s commitment to continuous improvement, providing a platform that enhances efficiency, accountability, and quality control.Whether producing components for the medical industry or delivering aerospace machining by McCormick Industries, the company remains steadfast in its dedication to precision and reliability.

By integrating ProShop into its daily operations, McCormick Industries has strengthened its ability to meet customer demands while ensuring long-term sustainability. As the company continues to refine its processes and embrace digital advancements, it remains well-positioned to serve industries that require the highest standards of accuracy and performance.

###

For more information about McCormick Industries, contact the company here:

McCormick Industries

Gary Hermsen

920-954-9648

info@mccormickind.com

1103 South Perkins Street

Appleton, WI 54914